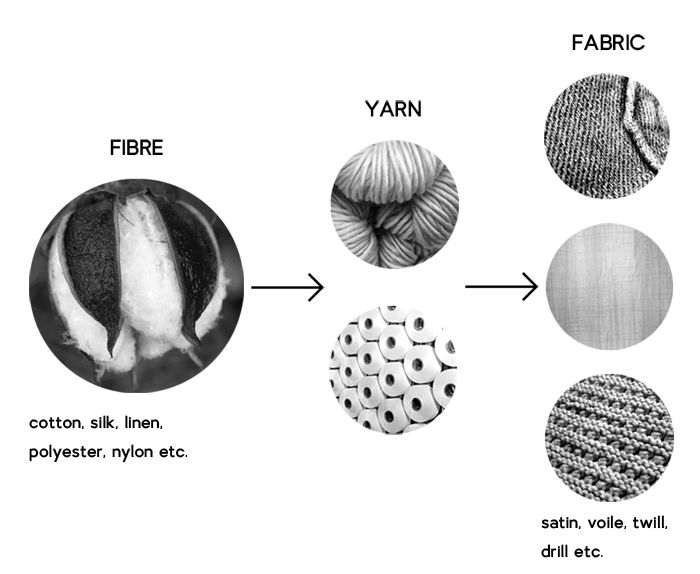

With industrialization and mass production, we quickly forgot the multitude of steps that hide behind the making of our clothes. For example, non woven bag manufacturers have also some simple steps in their factories.

Did you know that no less than nine steps are involved in the manufacturing process of our clothes? From the fiber to the finished product, it is these skills that we have chosen to highlight in this guide.

From the fiber, at least 5 steps are necessary to manufacture a garment. Fiber culture, spinning, weaving, dyeing, making.

Fiber

Whether it is linen, hemp or even cotton, you have to start somewhere. However, the culture of the raw material is at the very basis of making clothes. In the case of natural materials from plants, the operator sows, maintains and then harvests the fibers.

For example, for a garment made predominantly with cotton, after being harvested, the cotton fibers are sorted, cleaned to remove dirt and then spun. In order to facilitate spinning treatments, preparation agents (lubricants and humidifying agents) are used. These agents will then be eliminated and may end up in the wastewater. Working overall manufacturers have to select stiff and strong cotton fibers to make their yarns and fabrics.

Wiring

It is then the turn of the spinner to enter. Its role is therefore to transform raw material into thread. Simple as pie, right? Well, no! To achieve this result, the fibers are successively freed of their impurities, combed, drawn and then braided.

Weaving

There are several weaving methods depending on the desired result, we prefer this or that method. For example, the so-called “classic” weaving will make it possible to obtain more rigid fabrics such as jeans while the mesh will offer a more flexible result, ideal for making t-shirts. Chemical fibers are used by non woven bag manufacturers.

The weaving phase may require synthetic finishes, i.e. all chemical, physical and mechanical treatments, which serve to give textiles the desired end-use properties (touch, visual effect, waterproofing, non-flammability, etc.). This is the finishing phase. Towel manufacturers in Bangladesh are all weaving mills who make towel and sew by themselves.

The Dyeing

As with weaving, there are different skills. Indeed, this step is not frozen in time. Dyeing involves the use of a certain number of chemicals and auxiliary products which are generally found in waste. The environmental impacts considered at this stage are discharges from the dye baths; washing and rinsing baths after dyeing, equipment cleaning water. Textiles can be dyed during any phase of the manufacturing process depending on the presentation of the material (wadding, thread, fabric).

You can either choose to dye the yarn, the fabric, or the finished product “diving”. But that’s not all! When printing a pattern, it can be done in several ways: the frame, the block print from India, the batik, the shibori emblematic of Japan and many other techniques of the 4 corners of the world!

Sewing

This stage brings together all the textile materials, known as tailoring, which allow clothing to come to life. Before the actual sewing, the fabric is cut beforehand, but it is generally the same people who take care of these two stages. The pieces now shaped, are ready for assembly. The final details, such as embroidery or labels are then brought to it.

There are many ways to create different clothes in several forms:

Spinning: The production of a thread requires shelling and cleaning of the raw material (ginning), loosening and parallelization of the fibers (carding, combing) and finally spinning.

Weaving: The fabric is obtained by weaving which is the result of the intertwining, in the same plane, of threads arranged in the warp direction and of threads arranged, perpendicular to the warp threads, in the direction of the frame. The binding obtained between these warp and weft threads is defined by a weave. Jeans manufacturer in Bangladesh do both yarn dying and weaving under same roof.

Knitting: Several knitting methods have been developed.

The best known knitting, also known as weft knitting. It allows the production of jersey, interlock, 1×1 rib, English rib, etc. These knits are frequently used in underwear, T-shirts, pullovers, socks, etc.